Cleaning Skid Series

The cleaning skid is designed for manual

operation through a local control box located on

the skid. A chemical storage tank is mounted on

its own stand and connected to the skid with

either hard PVC piping or quick disconnect

fittings and flexible hoses. This gives the unit

the ability to be mounted in a permanent

location or totally portable if desired. The

piping is schedule 80 PVC that is

hydrostatically tested at the factory. The

electrical enclosure is NEMA 4X. All skid wiring

is completed and tested before shipment.

Standard Features

Skid mounted unit

Chemical solution tank with cover

PVC piping

316L Stainless cleaning pump

5 micron cartridge filter with stainless

steel housing (CS8) or polypropylene

(CS4)

Local flow meter

Tank level switch (CS 8)

220V/1Ph/60Hz or 460V/3Ph/60Hz |

Available

Options

220V/1Ph/50Hz or 380-415V 3Ph 50Hz

pH Controller

Electric heater for chemical tank with

temperature controller

Flexible hoses for cleaning connection

Wheel mounted skids for smaller units

Mixer

Applications

Membrane cleaning

Descaling |

Membrane Cleaning

Chemicals

Acid and alkaline cleaning chemicals are most

commonly used for membrane cleaning. Acid

cleaners are designed to remove inorganic and

iron deposits. Acid cleaning should be performed

at a pH of about 2. Alkaline cleaners are

designed for removal of biological matter,

organic foulants, and silica deposits. Alkaline

cleaning is performed at a pH of about 12.

|

Model No. |

Number of pressure vessels to be

cleaned at a time |

Pipe Material |

Pipe Size |

Tank Capacity |

Shipping Weight |

|

CS4-1 |

1 (4") |

Schedule 80 PVC |

1" |

50 |

300 |

|

CS4-2 |

2 (4") |

Schedule 80 PVC |

1" |

100 |

350 |

|

CS4-3 |

3 (4") |

Schedule 80 PVC |

1" |

150 |

375 |

|

CS8-1 |

1 (8") |

Schedule 80 PVC |

1.5" |

150 |

500 |

|

CS8-2 |

2 (8") |

Schedule 80 PVC |

1.5" |

200 |

600 |

|

CS8-3 |

3 (8") |

Schedule 80 PVC |

2" |

300 |

700 |

|

CS8-4 |

4 (8") |

Schedule 80 PVC |

2" |

360 |

800 |

|

CS8-5 |

5 (8") |

Schedule 80 PVC |

2" |

500 |

900 |

|

CS8-6 |

6 (8") |

Schedule 80 PVC |

3" |

625 |

980 |

Membrane Cleaning

Process

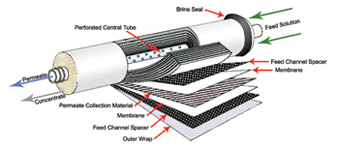

Reverse Osmosis membrane elements can experience

a decline in performance due to the accumulation

of deposits on the membrane surface. Mineral

scale, colloidal particles, biological matter,

and insoluble organic compounds are the usual

causes of membrane fouling. When production of a

Reverse Osmosis system drops by at least 10

percent, or the differential pressure increases

by 15 percent (over normal operating

conditions), membrane cleaning should be

performed. The following is a summary of the

design of CWG, Inc. cleaning stations and

cleaning chemicals. More details instructions

are available in the Operating and Maintenance

manual for the CWG, Inc. Cleaning

Stations.

The illustration

above represents a simplified spiral-wound

membrane element

|